Testing under relevant conditions for relevant results

We’ve all been there. Maybe we need to select a new (or replacement) material for a device. Or maybe we discovered an unexpected failure mode during the late stages of development, and we need to simulate the failure. In those situations, the go-to action is to consult handbooks or material datasheets to find whatever properties are appropriate. That is, we do the best with what we have. As my Ph.D. supervisor liked to say, “Don’t let perfect be the enemy of good.” In other words, don’t let an insistence on perfection get in the way of progress. But what if we can do a little bit better? What if we can drive more value by taking a more considered approach to the data that we use? So what does that look like? For that to happen, we need to move beyond the datasheet because regardless of how these properties are labeled—average or typical, or expected—they often are not useful for performance-driven design. For that, we need relevant properties (or performance data) determined from relevant tests.

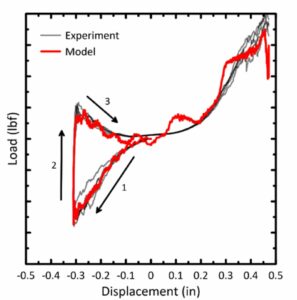

Figure 1. Reversed bending test of 250-micron diameter wire for constitutive model development

Sometimes the best-performing material may not be the material with the best handbook properties. In other words, a distinction must be made between properties, which are inherent to a material, and the performance of the material in some application, which is a measure of the capability of the material’s properties to fulfill some desired role. Performance may be further defined with respect to a manufacturing process—for example, castability, weldability, forgeability, or formability—or to the final use—for example, biocompatibility, energy absorption, wear resistance, or vibration dampening. In practice, both manufacturing performance and final use performance must be considered.

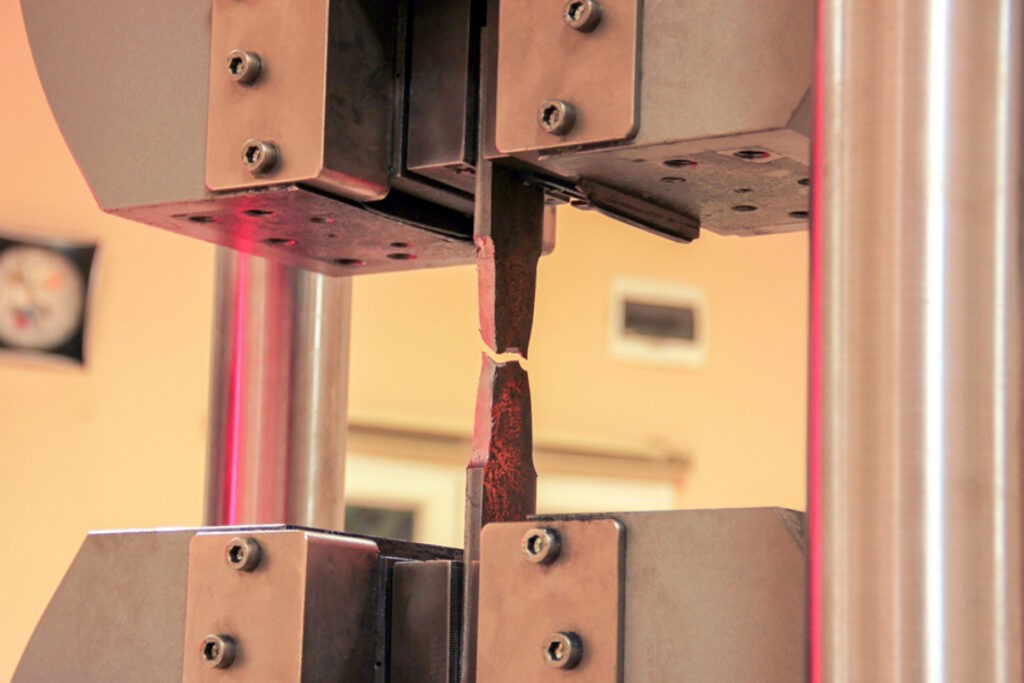

Implicit to this distinction is that the performance of materials—and devices—should be tested under relevant conditions. For example, there may be little value in testing at temperatures at which the active failure mechanisms are different than those active at temperatures typical of use. Or we shouldn’t base decisions on quasi-static properties when the critical performance needs (during manufacturing or end use or both) are at high-rate conditions. Additionally, testing under relevant conditions may require the use of customized test fixtures or environments.

Figure 2. Uniaxial tensile testing to determine material properties

Prudent materials and manufacturing process selection complemented with—and assisted by—relevant testing in the early stages of the design cycle can reap significant benefits later in a product’s lifecycle. These benefits include reducing time and resources spent on customer claims, recalls, and support of sub-tier suppliers. Ultimately, these benefits free limited resources to focus on developing the next generation of a product or the next new product.

AUTHOR

Dr. Erik Pavlina, Senior Associate, specializes in the processing and manufacturing of metals, materials selection, and failure analysis. He has extensive experience in manufacturing, industrial R&D and product development, and fundamental research in ferrous and non-ferrous alloys. Erik undoubtedly understands the challenges facing the production and application of materials to ever-increasing performance requirements. He has constantly strived to work on diverse teams to bridge the gap between materials and mechanical engineering to provide effective solutions.

Ref: B008-FA-Materials Datasheet Aren’t Wrong

Keep in touch with us.

Sign up for our newsletter.